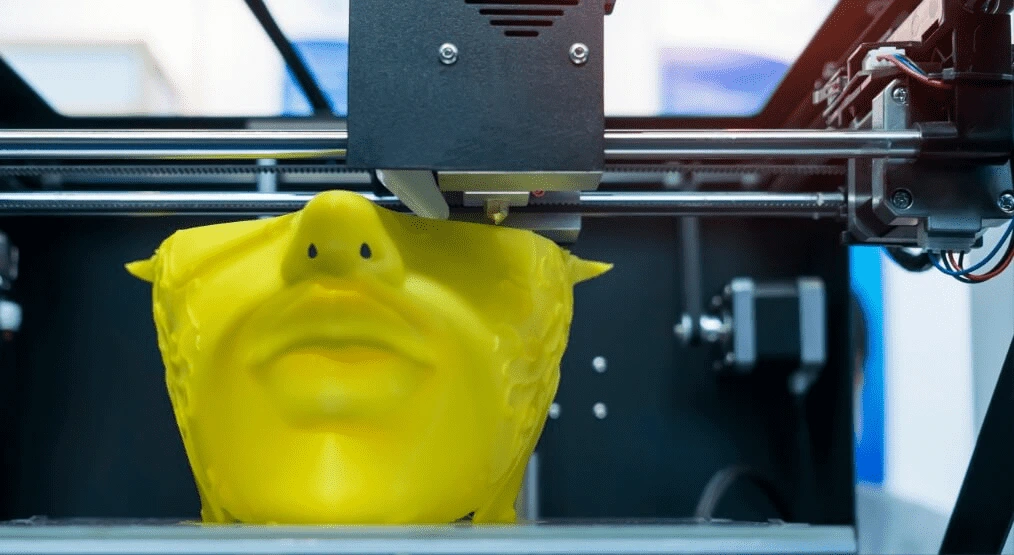

Let us bring your ideas to life with high-quality 3D printed production parts and prototypes. From design to deliver, Cardinal 3dp is your trusted resource for targeted

solutions to all your 3D printing needs.

Send us your 3D CAD file. Cardinal 3dp will then connect you with a member of the

team to discuss your goals and project expectations.

Your Cardinal 3dp representative will walk you through the ordering process to

identify which printing solution best fits your needs.

Once your order is placed, we get to work to bring your design to life.

The best part! Your order is complete and can be shipped anywhere in the United

States.

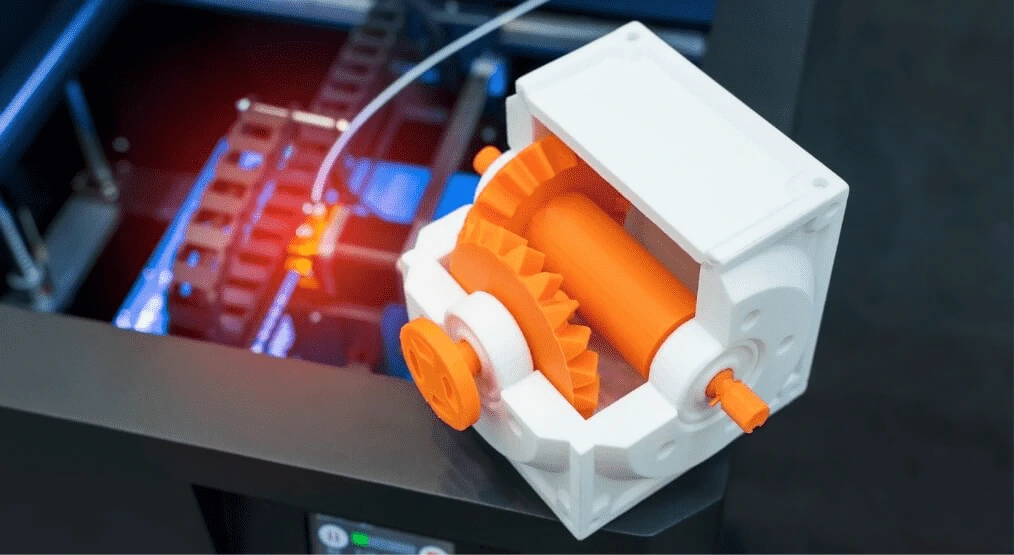

Cardinal 3dp was founded on the belief that a strong partnership, coupled with innovative technology, produces great results. We take pride in our ability to turn any idea, concept, or creation into a reality

through the scientific art of 3D printing. In today’s fast-paced digital world, you can trust us with your most valuable and scarce resource: time. For nearly a decade, Cardinal 3dp has streamlined the process of product development and prototyping into reliable solutions to your biggest challenges.

Cardinal 3DP makes custom 3-D printed products. High-quality is our focus. Therefore, we create everything in-house and regularly inspect all prints before shipping.

We have multiple printers for fused deposition modeling and different applications of stereolithography to be used with a variety of filament and resin materials. Our team will help you identify which technology and material best suits your needs

Cardinal 3dp provides simple modeling edits and design help for some projects. Please reach out for specific information about your design.

The Cardinal 3dp full-service experience provides one point of contact from start to finish. This guarantees a reliable partner who has a vested interest in your goals. We pride ourselves on the trust our clients put in us, and value the strong working connections that are created through the process.

Your wants and needs become ours

“We’ve hired Cardinal 3dp many times over the years to make all sorts of goods, from jigs and fixtures to replacement parts and upgrades for our machines. “

“when we first started prototyping our brackets, we learned quickly that minimum order production runs, even small ones, were costly. Although we had many variations 3d printed, the savings were significant and streamlined our process to the final product. “

Yes! Your privacy is important to us. Each response to requests through the website, automatically includes an NDA that covers our employee confidentiality obligations. Additionally, any content you see on Cardinal 3dp social media is posted only with written permission granted by our clients. Sometimes our customers are bringing a product to market and appreciate the extra help with their marketing efforts.

3D printing is currently one of most reliable and economically friendly processes for creating and perfecting production parts. Utilizing this technology allows our clients the opportunity to refine their designs with less upfront investment than that of mass production companies.

Yes. It is our policy to send a TDS for all filaments and resins used. We only use products that have appropriate documentation.

Production time varies depending on the technology, material, finish, size, print orientation, etc. Once we understand your project, your Cardinal 3dp representative will be able to offer an accurate estimate of product completion.

Highly Accurate